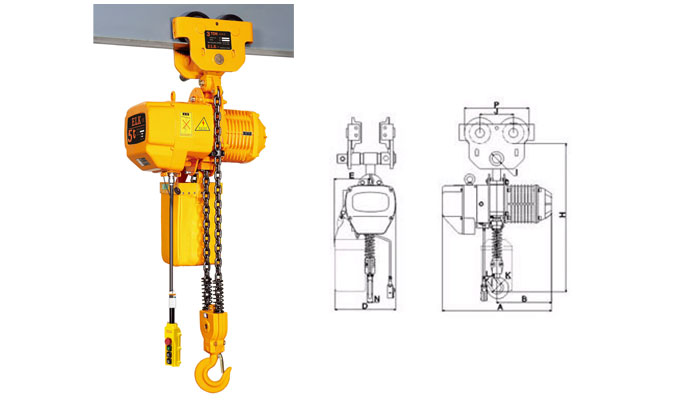

KBK light workstation bridge crane features modular track splicing, trolley and beam assembly installation process, ensure safe and stable operation.

KBK light workstation bridge crane has become the core handling equipment of modern workshops, assembly lines and warehousing logistics with its modular design, flexible layout and high cost performance. However, the full play of its performance is highly dependent on scientific and standardized installation processes. This article combines industry standards and practical experience to systematically explain the installation steps, technical points and common problem avoidance strategies of KBK cranes, helping enterprises to complete equipment deployment efficiently and safely.

Preparation and survey before installation

Site survey: Measure the net height, span and ground bearing capacity of the workshop to confirm whether the beam of the factory building needs to be reinforced.

Scheme design: According to the actual workstation layout and material flow direction, determine the track direction, bridge length, lifting height and electric control point position to form a complete installation drawing.

Track and support installation

Track assembly: Splice the aluminum alloy or steel track segments in sequence, and tighten them with positioning pins and special bolts to ensure accurate end-to-end docking.

Horizontal correction: Use a laser level to measure multiple points on the track, adjust the support or gasket to make the horizontal deviation ≤0.5 mm/10 m; at the same time, check the straightness to avoid running jams.

Bridge and trolley assembly in place

Bridge in place: Use auxiliary lifting equipment to lift the bridge structure under the track, move it slightly forward and backward, so that the bridge wheels are centered on the track and in place smoothly.

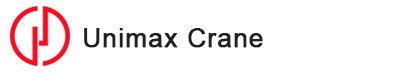

Trolley and hoist installation: Combine the manual or electric hoist with the trolley chassis and hang it on the bridge beam, adjust the verticality of the chain/wire rope, and ensure that the hook can rise and fall freely in the working area under the bridge.

Electrical control and safety device

Power supply wiring: Connect the power cable and control cable according to the design drawing, and all joints must be protected and well grounded.

Limit and emergency stop: Install travel limit switches, overload protection relays and emergency stop buttons to ensure that the equipment automatically stops and alarms in abnormal conditions.

Debugging and acceptance

No-load test run: First, power on and run without load to check the response speed, braking performance and noise level of the bridge travel and lifting system.

Full-load performance test: Use rated weight to perform multiple lifting and bridge movement to verify the reliability of slow start/slow stop, limit protection and overload functions.

Safety inspection: Finally, a professional will issue an acceptance report to confirm that the equipment runs smoothly and the safety device is sensitive before it can be officially put into production.

Through a rigorous installation process, KBK light workstation bridge crane can not only achieve fast and accurate material handling, but also minimize downtime and maintenance costs, helping enterprises to complete production tasks efficiently and safely. If you need more installation details or customized services, please feel free to contact our technical team.

You Might Also Be Interested In: KBK Aluminum Monorail Workstation Crane