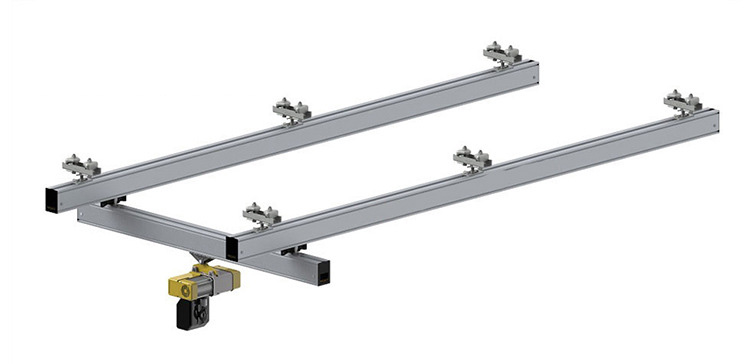

KBK modular workstation crane system is a flexible, efficient and safe rail-type lifting equipment designed to meet the material handling needs of production workshops, assembly lines, warehouses and other places. The system is based on light steel or aluminum alloy profile rails and adopts a modular design concept. It can flexibly configure single-beam, double-beam, suspension and other structural forms according to the layout of the work area to achieve accurate and safe material transportation between workstations.

The main advantages of KBK workstation crane

The main beam, rails, walking mechanism, etc. are all modularly designed, which can be freely combined according to the layout of the workshop, supporting a variety of running paths such as straight lines, curves and rings.

Matched with accessories such as electric hoists to meet different lifting needs.

No complex foundation is required and it can be directly installed on the steel structure or column of the factory building to save construction costs.

The lifting capacity covers 100kg - 2000kg, which is suitable for light to medium-sized material handling.

Smooth operation and low noise design are suitable for environments such as precision assembly and electronic manufacturing.

Typical application scenarios

Automobile manufacturing: engine, parts assembly line

Electronic industry: PCB board, precision instrument handling

Warehouse logistics: light cargo transfer, sorting

Food and medicine: material transportation in clean workshops

Why choose our KBK crane system

International technical standards, ensuring high precision and long life

Fast delivery, sufficient inventory of standard components, shortened delivery cycle

One-stop service, providing full process support for design, installation, commissioning and training

KBK modular workstation crane system has become an ideal handling equipment for modern smart factories with its flexible, efficient and economical characteristics. Click to contact us, and our engineers will provide customized solutions tailored to your production application requirements.