What processes need to be passed in the process of manufactu

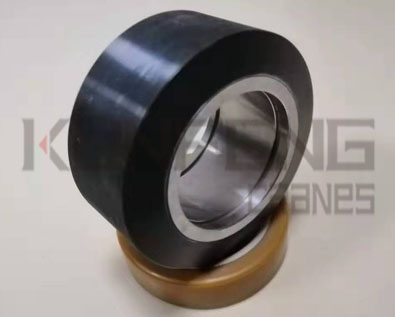

Many places are now responsible for the production of polyurethane rubber rollers, and the scope of application of encapsulation has also begun to increase.

Manufacturers can determine the color and standard size of materials according to practical needs in the process of manufacturing encapsulation, so that the polyurethane encapsulation can reach Better application purpose, and provide convenient conditions for production work. So what process needs to be passed in the process of manufacturing encapsulation?

Here is a brief introduction to this problem. In the process of manufacturing polyurethane rubber rollers, it is necessary to clean the encapsulation first. If a new iron core is used for processing, then the cleaning process is essential. In the actual production process, many polyurethane rubber roller manufacturers use comparison The old iron core is used to make the encapsulation. If this is the case, it is necessary to remove the outer layer of the encapsulation, and a cleaning process is also required, so that the quality of the encapsulation is better and can achieve the desired application purpose. In the actual production process, the manufacture of polyurethane encapsulation also requires rough processing procedures. When performing these processing procedures, it is necessary to pay attention to the practical touch area of the iron core and materials. Only by ensuring the size of the touch area can the manufacturing effect of the encapsulation be improved. it is good. In addition, during the sandblasting process, it is necessary to process the rough iron core to ensure that the material and the iron core fit better. These are the methods and techniques that need to be paid attention to during the process. In the process of manufacturing polyurethane rubber rollers, the model and standard size of the encapsulation must be determined in advance, so that the materials made can meet the practical needs of customers. If there are certain errors, they must be adjusted in time according to customer requirements.

Manufacturers can determine the color and standard size of materials according to practical needs in the process of manufacturing encapsulation, so that the polyurethane encapsulation can reach Better application purpose, and provide convenient conditions for production work. So what process needs to be passed in the process of manufacturing encapsulation?

Here is a brief introduction to this problem. In the process of manufacturing polyurethane rubber rollers, it is necessary to clean the encapsulation first. If a new iron core is used for processing, then the cleaning process is essential. In the actual production process, many polyurethane rubber roller manufacturers use comparison The old iron core is used to make the encapsulation. If this is the case, it is necessary to remove the outer layer of the encapsulation, and a cleaning process is also required, so that the quality of the encapsulation is better and can achieve the desired application purpose. In the actual production process, the manufacture of polyurethane encapsulation also requires rough processing procedures. When performing these processing procedures, it is necessary to pay attention to the practical touch area of the iron core and materials. Only by ensuring the size of the touch area can the manufacturing effect of the encapsulation be improved. it is good. In addition, during the sandblasting process, it is necessary to process the rough iron core to ensure that the material and the iron core fit better. These are the methods and techniques that need to be paid attention to during the process. In the process of manufacturing polyurethane rubber rollers, the model and standard size of the encapsulation must be determined in advance, so that the materials made can meet the practical needs of customers. If there are certain errors, they must be adjusted in time according to customer requirements.

DEMAGE electric chain hoist

DEMAGE electric chain hoist DEMAGE hoist

DEMAGE hoist Characteristics of Kito electric chain hoists

Characteristics of Kito electric chain hoists KITO EQ Series Electric Chain Hoist for Sale

KITO EQ Series Electric Chain Hoist for Sale Demag chain hoists

Demag chain hoists